Hot Melt Extrusion

In order to develop innovative formulations of medicinal products, specialists at Pikralida use cutting-edge drug manufacturing technologies, such as the hot melt extrusion (HME) technique.

In order to develop innovative formulations of medicinal products, specialists at Pikralida use cutting-edge drug manufacturing technologies, such as the hot melt extrusion (HME) technique.

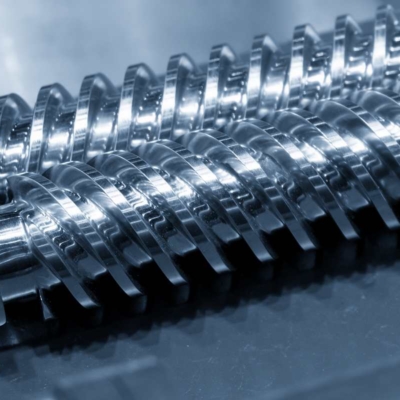

Plasticization of the raw material due to high temperature and pressure, combined with passing it through a die with an appropriate profile, yield a product of uniform shape and density. For the HME process to be viable, the polymers used in the hot melt extrusion process need to have suitable thermoplastic properties and to be thermally stable at extrusion temperatures.

The hot extrusion technique is a modern and efficient technological process, given the uniformity of the resulting product, no need for solvents and guaranteed continuous production.

Obtaining solid molecular dispersions of APIs by forming solid solutions may improve the solubility and bioavailability of active substances with low water solubility. Moreover, the HME technique allows for masking the taste of active substances and for obtaining modified release drug forms, such as extended-release tablets or fast-disintegrating dosage forms.

Pikralida provides services for the development of technology for the active substances amorphization

based on the use of the hot extrusion process as well as the formulation development of medicinal products containing the amorphous form of the active substance.

The purchase of the Process 11 Hygenic extruder from Thermo Scientific and the introduction of a specialized service to the company’s offer were carried out as part of the project entitled “Developing a R&D supergeneric laboratory”, co-financed by European Funds.

Ekstruder Process 11 Hygenic firmy Thermo Scientific was supplied and installed by RHL-Service