Drug Delivery Systems

Innovative formulations of medicinal products are essential when it comes to the development of innovative and effective treatment methods. The most common challenges faced by modern drug therapy include the development of formulations for low solubility substances and the development of delivery systems for drugs that modulate the release profile of the active substance.

At Pikralida, we have set up an R&D laboratory for super generic drugs, where we use modern technologies such as hot melt extrusion that make it possible to solve problems associated with the solubility and bioavailability of active substances. The use of this technology also allows for designing and developing various drug forms, including forms with a modified release profile of the active substance, e.g. sustained-release tablets or implants.

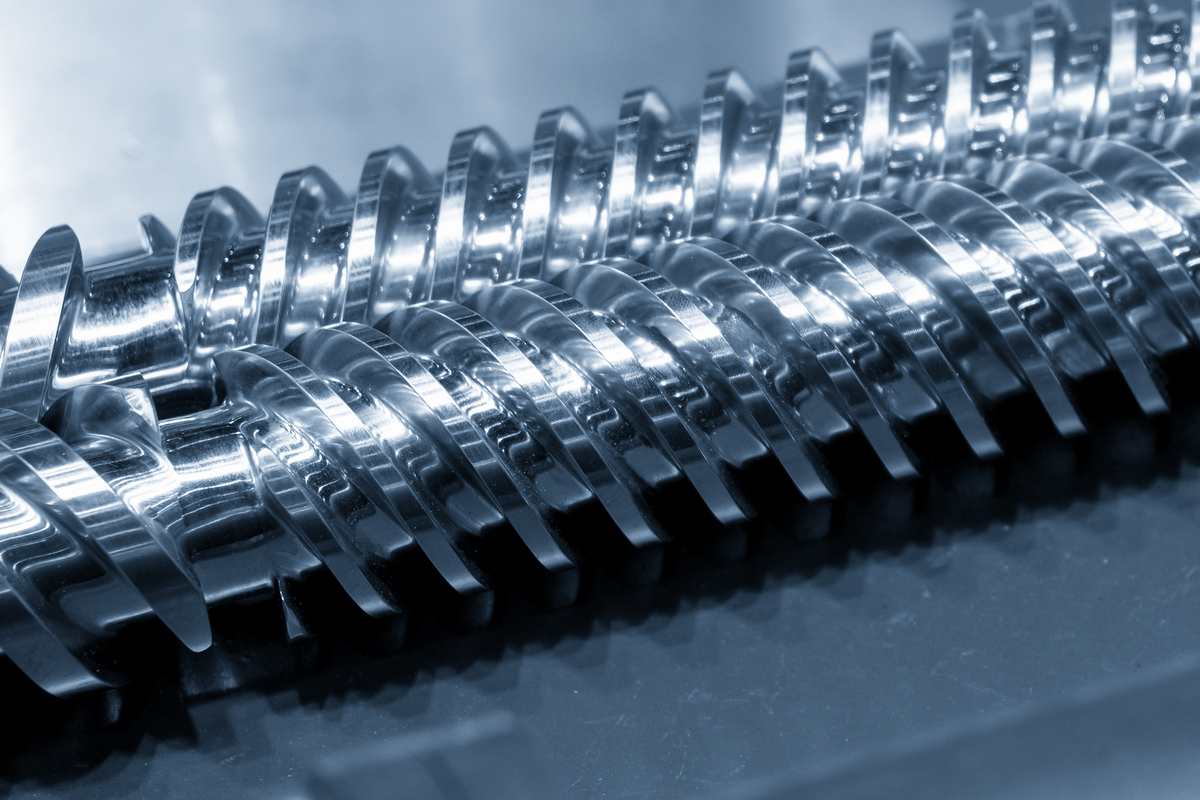

Hot Melt Extrusion

The hot melt extrusion (HME) technique is a modern and efficient technological process used in the pharmaceutical industry to obtain a solid drug formulation. The method involves dispersing the therapeutical substance in a polymer melt, followed by the extrusion of the resulting mixture. For the HME process to be viable, the polymers used in the hot melt extrusion process need to have suitable thermoplastic properties and to be thermally stable at extrusion temperatures. Plasticization of the raw material due to high temperature and pressure, combined with it passing through a channel with an appropriate profile, yield a product of uniform shape and density. The final form of the drug may be formed directly from the extrudate obtained (such as implants) or by combining it with selected excipients (such as tablets).